Cleaning of landfill filtrate

Currently, there are about 800 landfills of various sizes in Lithuania, some of which are still in operation. During the operation of the landfill, the filtrate is formed, which is usually stored in open ponds and is then transported/pumped out to domestic wastewater treatment plants. However, often this method of landfill leachate management (direct biological treatment) is unacceptable or prohibited due to the high toxicity of the leachate to the activated sludge, related to the large heavy metals, priority substances, ammonium nitrogen, organic carbon, etc. found in the leachate.

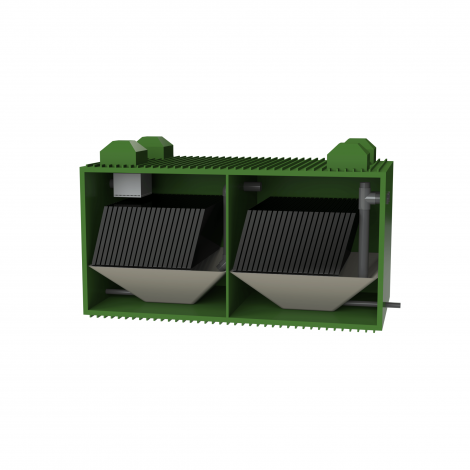

Currently, various technology combinations are used to clean the landfill filtrate, otherwise called “technology trains”, when the cleaning process consists of several sequentially operating devices. The choice of the exact devices is strongly influenced by the age of the landfill, and the composition of the accumulated waste, so each case is individual when choosing a treatment technology. We can offer chemical, physicochemical, and biological treatment devices for landfill filtrate cleaning. Before installing real devices, we always recommend to our customers to conduct pilot studies, when the most efficient and most suitable leachate treatment technologies are selected for a specific landfill. Most of the landfill leachate treatment “technology train” consists of preliminary treatment (DAF flotation or traditional coagulation/flocculation), ozonation, biological treatment, and/or membrane filtration. However, the exact choice of cleaning equipment depends on the specific object and is coordinated individually.