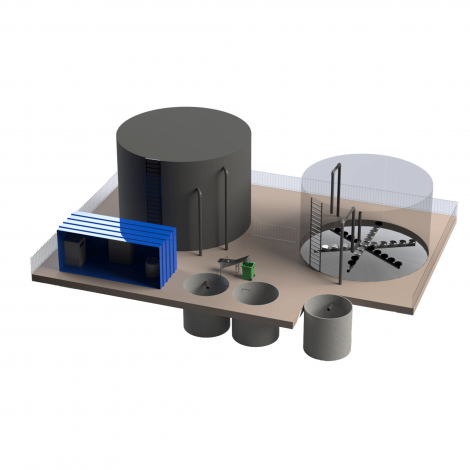

SBR – industrial wastewater treatment

Sequence biological reactors (SBRs) can also be easily adapted to treat industrial wastewater of various compositions. SBR reactors can be integrated into the overall composition of a wastewater treatment plant together with other operating technologies, e.g. dissolved air flotation (DAF), activated carbon filtration, or ozonation. SBR systems for industrial wastewater treatment are equipped for various capacities ranging from 1 to 400 m3/hour.

Using our complete SBR systems, it is possible to meet even the most strict requirements for wastewater that are discharged into networks operated by domestic wastewater treatment plants or the natural environment. In addition, SBR setups can be installed already in the existing tanks at the customer’s facility, thus saving the costs required for the construction. During the operation of the installed SBR reactors, electricity consumption is significantly reduced due to the innovative design of the reactors and the precisely controlled aeration process.

Advantages of SBR systems for industrial wastewater treatment:

- Low cost of construction and operation of equipment;

- SBR equipment can be installed in any form of new and/or existing concrete, fiberglass, or polyethylene containers;

- Guarantee that the required cleaning efficiency level of wastewater treatment will be achieved;

- Additional integration of phosphorus removal and disinfection processes is possible;

- SBR systems are selected following DIN EN 12566 and DWA requirements;

- Fully automated wastewater treatment process;

- Exceptionally easy programming and modification of cleaning cycles.